Hanger Bolt Factory Guide: Finding the Best Solutions

2026-01-07

Finding the right hanger bolts for your project can be a daunting task. With so many manufacturers and options available, it's easy to feel overwhelmed. In this guide, we'll cut through the noise and provide practical insights into selecting high-quality hanger bolts. As a trusted name in the industry, Topfence has extensive experience in delivering durable solutions for various applications. Get ready to discover expert tips that will help you make informed decisions and ensure your projects stand the test of time.

What is a Hanger Bolt? An Introduction to Its Function and Uses

A hanger bolt is a unique fastener that combines the features of a bolt and a stud, typically used in woodworking and furniture assembly. It has a lag screw thread on one end, designed to bite securely into wood, while the other end features machine threads suitable for attaching metal parts, like nuts or other fasteners. This dual-thread design makes hanger bolts ideal for creating strong, permanent connections between wood and metal components.

Hanger bolts serve a crucial function in applications where both parts need to remain aligned and stable. They are often employed in furniture construction, such as attaching table legs to aprons or connecting wooden frames to metal brackets. By providing a sturdy anchor point, hanger bolts help prevent wobbling and wear over time, ensuring durability and reliability in various structural assemblies.

Beyond furniture, hanger bolts find uses in a range of scenarios, including deck building, where they might secure railings, or in DIY projects that require mixed-material joints. Their versatility and strong grip make them a go-to choice for both professionals and hobbyists looking to achieve robust, long-lasting connections without the need for complex tools or extensive modifications.

How to Choose the Right Material for Your Hanger Bolts

Selecting the ideal material for hanger bolts is less about following a rigid checklist and more about understanding the unique demands of your project. Start by considering the environment where the bolts will be installed—will they face constant moisture, extreme temperatures, or corrosive chemicals? For instance, if you're securing outdoor furniture that endures rain and sun, stainless steel might be your go-to due to its rust-resistant properties, while in dry indoor settings, carbon steel could suffice to keep costs down.

Beyond just durability, think about the aesthetic and functional aspects that often get overlooked. Materials like brass or bronze aren't just for show; they offer excellent corrosion resistance and can blend seamlessly with decorative fixtures, adding a touch of elegance without compromising strength. On the other hand, if you need a material that's easy to machine and weld, mild steel might be more practical, especially for custom applications where adjustability is key.

Lastly, don't forget to factor in budget and availability—while exotic alloys like titanium provide unbeatable strength-to-weight ratios, they might be overkill for a simple bookshelf project. Balancing performance with practicality ensures your hanger bolts not only hold up but also fit seamlessly into your overall design, making the choice as much about smart planning as it is about material science.

Common Applications of Hanger Bolts in Woodworking and Furniture

In woodworking shops, hanger bolts serve as a robust connector for joining wooden components in furniture pieces like chairs and tables. They are often used to attach legs securely to tabletops or frames, ensuring durability under stress. Their dual-thread design—one end with a wood screw and the other with a machine thread—allows for a tight fit in wood while accommodating nuts or washers on the other side, which is handy for adjustable or replaceable parts.

Beyond structural support, these bolts find a niche in custom projects, such as mounting hardware on cabinets or attaching casters to heavy furniture for mobility. Their versatility shines when combining different materials, like fastening metal brackets to wooden surfaces, which prevents wobbling and extends the lifespan of handmade items.

For DIY enthusiasts, hanger bolts offer a clever solution for hidden joins in items like bed frames or bookshelves, maintaining a clean aesthetic without visible screws. This feature makes them a favorite in high-quality furniture where both strength and appearance matter, blending functionality with seamless design.

Step-by-Step Installation Tips for Hanger Bolts

Installing hanger bolts can seem tricky at first, but with a few simple techniques, you'll have them securely in place in no time. Start by choosing the right pilot hole size—typically a bit smaller than the bolt's thread diameter to ensure a tight grip. Pre-drill carefully, keeping the drill straight to avoid splitting the material. It's a good idea to use a depth stop on your drill to prevent drilling too deep, as this can weaken the hold. For wooden applications, consider applying a bit of wax or soap to the threads to reduce friction and make screwing easier, while always wearing safety goggles to protect your eyes from debris.

Next, align the bolt correctly with the hole; if you're dealing with a two-ended hanger bolt, one side often has a wood screw thread for embedding in wood, and the other a machine thread for attaching hardware. Use a wrench or a specialized hanger bolt driver to turn it in, applying steady pressure. Avoid over-tightening, as this can strip the threads or damage the material. For smoother installations in dense woods, you might try using a clamp to hold the workpiece firmly, reducing any wobble that could lead to misalignment. This step-by-step approach helps prevent common pitfalls and ensures a more durable installation.

Finally, test the bolt's stability by gently wiggling it to check for any looseness; if it feels secure, you're all set. Remember to clean up any wood shavings or metal filings left from the process to maintain a tidy workspace. Different materials might require slight adjustments—for instance, in metal or plastic, you may need to use a tap to create threads first. Keep a few spare bolts on hand in case of mistakes, and practice on scrap pieces if you're new to this. With these practical tips, hanger bolt installations become straightforward, saving time and improving results in various DIY or professional projects.

Comparing Manufacturers: Quality Standards in Hanger Bolt Production

When evaluating manufacturers of hanger bolts, quality standards play a crucial role in ensuring reliability and safety across various applications, such as machinery assembly and furniture construction. Differences in production approaches can significantly impact the bolts' durability, corrosion resistance, and overall performance. Manufacturers often adhere to distinct protocols, ranging from adherence to industry certifications like ISO 9001 to implementing proprietary testing methods that check for material consistency and load-bearing capabilities. Understanding these variations is key to selecting bolts that meet specific project requirements without compromising on integrity.

A deeper dive into production processes reveals that not all manufacturers prioritize the same aspects of quality. Some may focus on rigorous raw material sourcing, using high-grade steel or specialized coatings to enhance longevity in harsh environments, while others might emphasize precision in threading and dimensional accuracy to ensure seamless installation. These factors directly influence the bolt's ability to withstand stress and prevent failures, making it essential to compare how each manufacturer verifies quality at different stages, from initial forging to final inspection, to avoid costly issues down the line.

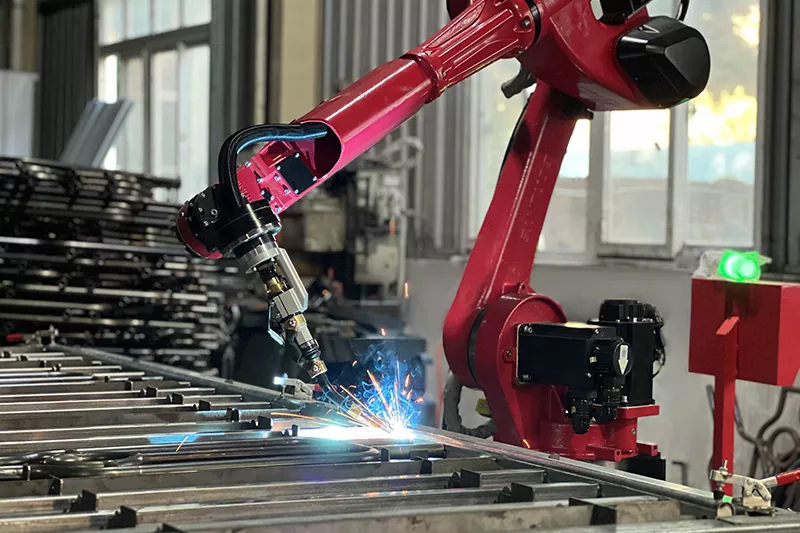

To stand out in the competitive landscape, forward-thinking manufacturers are increasingly incorporating advanced techniques such as automated quality checks and real-time monitoring systems during production. This not only minimizes defects but also ensures consistency across batches, a critical factor for large-scale projects. By examining these innovations alongside traditional metrics, buyers can make informed decisions that balance cost-effectiveness with superior performance, ultimately leading to more reliable installations and reduced maintenance needs over time.

Custom Hanger Bolt Solutions for Unique Project Requirements

When standard hardware falls short, custom hanger bolts provide a tailored fix. These specialized fasteners are designed to meet specific project demands, from unusual materials like stainless steel for outdoor use to unique dimensions that fit uncommon joint configurations. Think of them as bespoke connectors that integrate seamlessly into custom furniture, marine applications, or industrial setups where off-the-shelf options just won't do. With options like varied thread patterns, lengths, and head styles, you can solve issues like load distribution or aesthetic alignment that generic bolts often miss.

Custom hanger bolts aren't just about size adjustments; they address functional nuances that boost project durability. For instance, in heritage restoration where original fittings are non-standard, a custom bolt can replicate historical accuracy while using modern alloys for strength. We've seen projects in robotics where modified thread pitches prevent loosening under vibration, or in art installations requiring flush mounting without visible hardware. By collaborating with manufacturers, you can specify coatings for corrosion resistance or incorporate features like integrated washers, ensuring each bolt performs reliably in its unique environment without compromising design intent.

Working with custom solutions means thinking beyond the catalog. It's a process that starts with identifying project-specific challenges: maybe it's a need for left-hand threads in machinery or a low-profile head for safety in high-traffic areas. Customization allows for prototypes and testing, so you can refine details like torque ratings or installation methods before full-scale production. This approach not only solves immediate problems but also innovates, as seen in green building projects using eco-friendly materials or in aerospace where weight savings are critical. Ultimately, it's about crafting fasteners that elevate your project from functional to exceptional, with every bolt designed to fit your vision precisely.

FAQ

When choosing a factory, prioritize technical expertise, material quality assurances, and adherence to industry standards like ASTM or ISO. Look for suppliers with robust quality control processes and experience in your specific application, whether it's furniture, automotive, or construction, to ensure bolts meet your performance needs and durability expectations.

Factories offer customization in thread sizes, materials, coatings, and lengths. Discuss your project's load requirements, environmental conditions, and installation methods. A good factory will provide prototypes or samples, using CNC machining or specialized tooling to produce bolts that fit precisely, enhancing both functionality and longevity in your applications.

Expect factories to conduct dimensional checks, tensile strength tests, and corrosion resistance assessments. They should use advanced equipment, maintain detailed inspection records, and follow certifications such as ISO 9001. Regular audits and batch testing ensure consistency, minimizing defects and ensuring safety in finished products.

Material choice directly impacts strength, corrosion resistance, and cost-effectiveness. Steel alloys, stainless steel, or brass are common; for instance, stainless steel suits outdoor use due to rust prevention, while hardened steel handles high loads. A factory can advise on the best material based on your budget and environmental factors.

Lead times vary by order size and complexity; efficient factories streamline production with just-in-time inventory. Consider logistics for shipping and storage—bulk orders may benefit from cost savings but require planning. Reliable factories offer transparent timelines and flexible options to avoid delays in your supply chain.

Issues include thread precision, material defects, and coating uniformity. Factories tackle these with skilled technicians, automated machinery for consistency, and rigorous testing. They often use feedback loops to refine processes, ensuring bolts meet tolerances and perform reliably under stress without premature failure.

Yes, many factories provide engineering support to optimize designs for efficiency and cost. They might suggest alterations in thread pitch or head style to improve grip or ease installation. This collaboration helps avoid over-engineering, reducing material waste and ensuring the bolt design aligns with your project's specific demands.

Conclusion

This guide serves as a comprehensive resource for selecting and utilizing hanger bolts, drawing on expertise in materials, applications, installation, and manufacturing. Hanger bolts are dual-ended fasteners featuring a wood screw on one side and a machine screw on the other, making them ideal for joining wood to metal, such as in furniture legs or machinery mounts. When choosing materials, factors like corrosion resistance (e.g., stainless steel for outdoor use) and load capacity (e.g., steel for heavy-duty tasks) are crucial for durability. Common uses in woodworking and furniture include securing table bases, bed frames, and cabinetry, where their design ensures a strong, hidden connection. Installation involves pre-drilling pilot holes, using a wrench or specialized tool to drive the bolts, and checking alignment to prevent wood splitting, with tips for smooth execution. To find the best solutions, compare manufacturers by assessing quality standards like ISO certification, material traceability, and consistent threading, which impact reliability. For unique projects, custom solutions offer tailored lengths, threads, or coatings, ensuring a perfect fit for niche applications.

By integrating these aspects, the guide helps users navigate options from basic fasteners to advanced custom designs. It emphasizes practical advice, such as matching bolt material to environmental conditions (e.g., zinc-plated bolts for indoor use) and considering load distributions in applications like shelving or structural supports. Installation techniques are detailed for precision, including using thread-locking compounds or spacers in complex setups. When evaluating manufacturers, look beyond price to factors like production capacity, lead times, and customer support for optimal sourcing. Custom solutions can address specific needs, such as non-standard diameters or special finishes, enhancing project outcomes. Overall, this guide empowers decision-making with a focus on quality, functionality, and innovation, ensuring users find efficient and effective hanger bolt solutions for diverse industrial and DIY scenarios.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/